Crabtree Services:

Today I am writing to try to inform consumers about an awful myth that is being spread around both by some HVAC distributors and HVAC technicians that there are “drop in” refrigerants that will affect homeowners to make uneducated decisions or choices by not being properly informed. This myth can in fact cost the consumer or homeowner more money in the long run versus if it was proposed the correct way. These statements about a drop-in refrigerant simply just isn’t true. I have been in the HVAC business 25 years and we are still learning every day because of new products and new manufacturer processes but this supposed drop-in refrigerant myth goes against everything that I’ve been taught and have used as a standard for all these years. I feel that this is just simply not providing an honest service, a proper AC repair, nor is it giving the full story to a consumer. It’s very disappointing to hear that our industry is using more and more short cuts every day that don’t align well with ethical practices. This is defacing our industry to make a quick dollar I believe. Here is an actual statement about R-427A from a refrigerant manufacturer.

Forane by Arkema states about this myth:

Over the years, refrigerant suppliers looking to sell product have targeted contractors looking for the easiest path for servicing equipment, and the hope of “drop in” refrigerants has become common. The term “drop in” dates back to the phase-out of chlorofluorocarbons (CFCs). Though CFCs have many properties that lead them to be considered ideal refrigerants, they are also recognized ozone depleting substances and, so, were phased-out in favor of more environmentally sustainable alternatives. During the transition away from CFCs, “interim” refrigerant blends containing hydro chlorofluorocarbons (HCFCs), such as R22, were developed to be used in existing R12 and R502 equipment. These HCFC-containing blends had a high degree of miscibility with the mineral oil used in existing CFC equipment. Retrofitting of the equipment with these interim blends could be done with fewer concerns with oil management, making the retrofits relatively easy and leading to their description as “drop ins.”

Crabtree Services:

They ended this article about this myth by saying:

Forane by Arkema states:

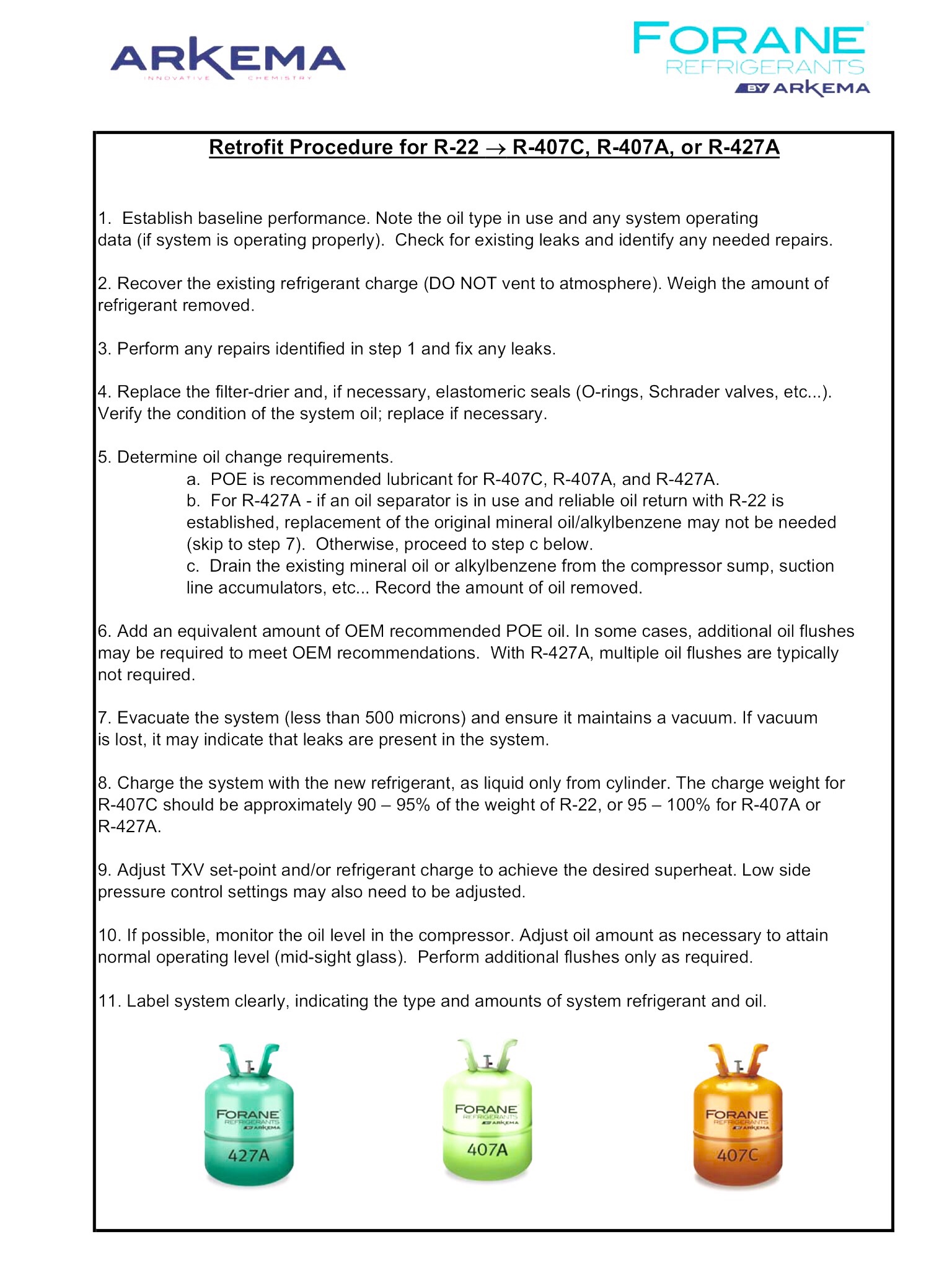

Regardless of this, some refrigerant suppliers have taken to describing these HC-containing HFC blends as “drop in” retrofits for R22, even where they still recommend that the oil be changed to POE. Arkema Inc. does not advocate the use of the term “drop in” as we believe the term implies a technician can just “drop” the refrigerant into an R22 system without doing any other work. Or even worse, interpreting “drop in” as to mean being able to top off an existing R-22 charge with a retrofit refrigerant. A proper retrofit should involve the following: Evaluating the system to determine whether the layout itself will prove difficult for oil return (eg. long line sets, vertical risers with evaporators that were not trapped correctly, etc…); conducting an oil analysis to confirm oil quality; installing a new filter dryer; installing new Schrader valves; leak checking the system and repairing any leaks. Once these steps are completed the technician can recharge the evacuated R-22 system with the retrofit gas. We do not believe this is considered “dropping it in.” When it comes to drop in’s, the truth is that there are none.

Crabtree Services:

I have heard both suppliers and technicians say to keep the expense down of adding R-22 to a system just top it off with a “drop in refrigerant. As stated above this is not a proper procedure. I have proven to my customers it’s not all about money but the ethical repair for I’ve saved numerous customers money but by using proper business practices. By providing the correct procedures and giving options for an AC Repair. So before agreeing to this myth let’s see what the same refrigerant manufacturer says for proper retrofitting is.

Forane by Arkema states proper retrofitting steps:

Step 1: Establish baseline performance

Check the system for leaks and identify any needed repairs. Run the system using the correct OEM charge of R-22 and record performance parameters using an Arkema Retrofit Data Sheet.

Step 2: Recover existing R-22

Recover existing R-22 refrigerant (DO NOT vent to the atmosphere) and make sure not to mix with other refrigerant gases. Record the weight of refrigerant removed.

Step 3: Check lubricant

A lubricant change may not be required, but POE is always recommended for optimal performance. Confirming oil quality isimportant. Check the oil for moisture, acidity, and metal shavings or sediments. If the oil does not meet the desired specification, acomplete oil change using POE is recommended. Systems with complex piping schemes could impede proper oil return. In these cases, adding or changing over to POE is recommended.

Step 4: Replace the filter dryer and seals

Replace the filter dryer and, if necessary, elastomeric seals and gaskets, such as Schrader valve cores.

Step 5: Leak check and evacuate the system

Conduct a pressure test using dry nitrogen to determine if the system has a leak, staying below the system pressure limitations. Repair any leaks as necessary. Pull a minimum vacuum of 500 microns and ensure that it maintains a vacuum. If the system does not hold vacuum, leaks may still be present.

Step 6: Charge the system with Forane®427A (R427A)

Remove refrigerant as a liquid only from the cylinder, being carefulnot to damage the compressor. The initial weight should beapproximately 95% of the original charge for R-22, charging up to 100% if necessary.

Step 7: Start the system and check performance

Start the system and record system performance, noting superheat and subcooling. Adjust TXV set-point and/or refrigerant charge

to achieve the desired superheat. Low side pressure control settings may also need to be adjusted.

Step 8 : Label the system

Properly label the system as being retrofitted with Forane® 427A (R427A).

Crabtree Services:

There are also other refrigerants such as M099 (R-438A) that is included in this myth, simpler said there is no quote “DROP-IN” refrigerants if you take a chemical makeup and add it to another chemical makeup you invented a new chemical makeup.

Not to mention there will be a great amount of work, materials and cost to properly perform this retrofit. Many manufacturers are using a fixed txv not a adjustable one so again more cost as well some manufacturers have warranty issues with these retrofits. Its in the consumers best interest to have in writing that the retrofit won’t effect any equipment warranties. I have listed some links below so that you can do your own research.

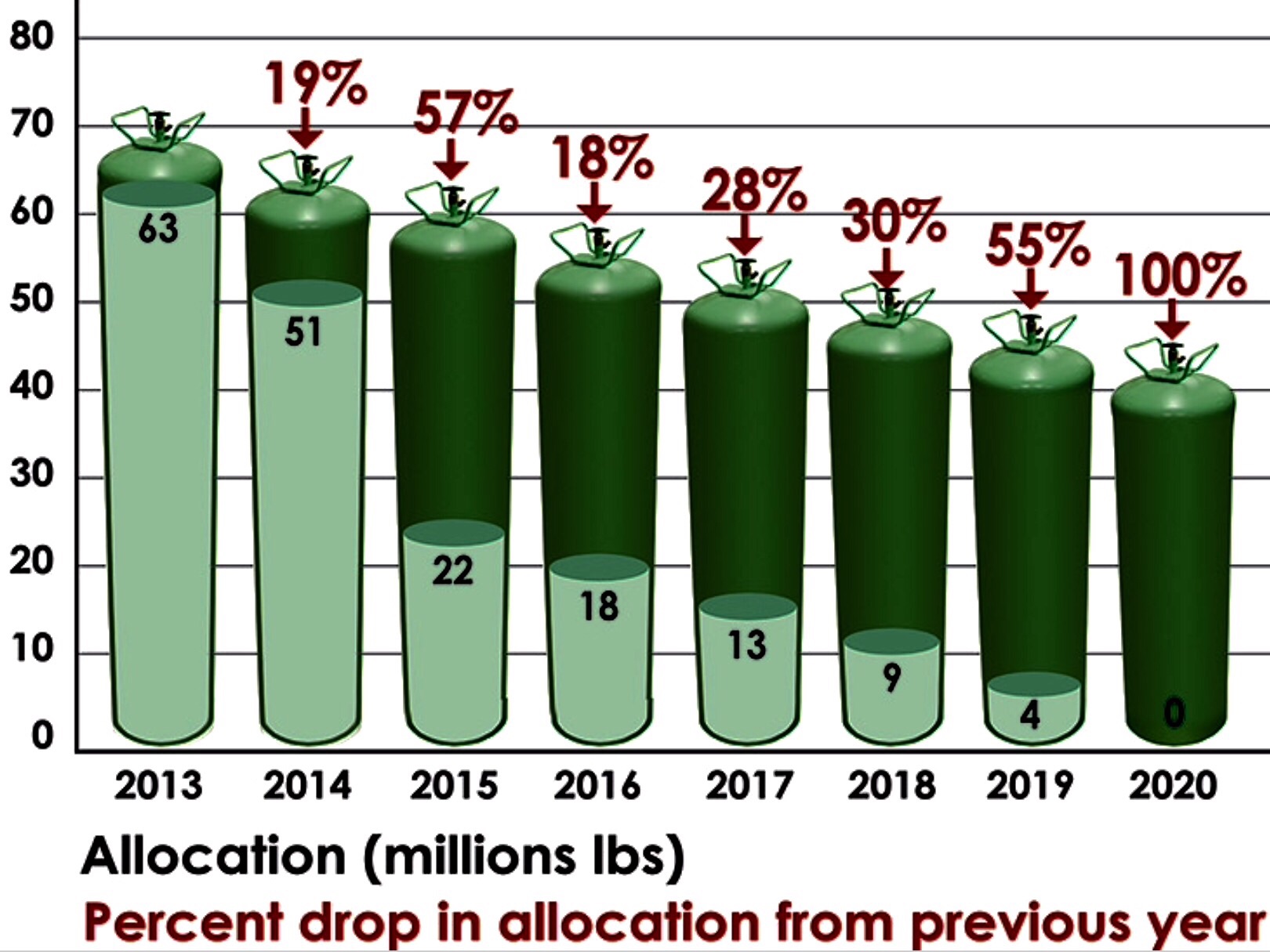

All this is resulting in the phase out of R-22 refrigerant that is being administered to the graph below and will show you at what rate.

In closing I hope this article will help both consumers and the industry that we appreciate and that we strive to serve with honesty and integrity every day.

References:

http://americas.forane.com/en/forane-refrigerants/forane-retrofits/forane-427a-retrofit-guides/

https://www.chemours.com/Refrigerants/en_US/assets/downloads/freon-m099-retrofit-guidelines.pdf